CNC Cutting Services- We specialize in CNC cutting of molds, kit boats, tooling,

and parts for composite applications. We also specialize in 3d CAD modeling and

can create precision 3d CAD models from your existing part, idea, or sketch.

Accuracy and Service Our small dedicated staff insures that your projects are treated

with care, respect, and urgency. If you are an America’s cup team, a small aerospace

company, or an individual boat builder, we want to make sure our services meet or

exceed your expectations.

Materials We can machine many materials on our CNC machines including foam, composites,

carbon fiber, fiberglass, aluminum, wood, and plastics. Recently we have been working

with environmentally friendly composite materials such as- flax fibers, basalt fibers,

100% recycled PET foam cores, cork, and bio based resin systems.

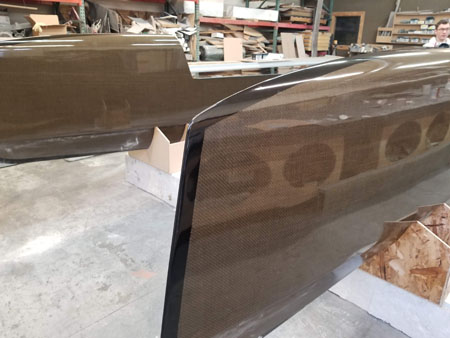

Prototype Power Catamaran- Turn Point Design was contracted to design and build 28’

foil assist catamaran hulls from environmentally friendly materials– flax fiber replaced

the fiberglass, recycled PET foam core, and bio-based epoxy resins. We also built

a set of curved carbon fiber hydrofoils for this boat from Pre-preg carbon fiber.

The hull design was optimized for efficiency with 70% of the hull weight supported

by the hydrofoils and went through 10 rounds of CFD optimization by before the build.

22’ Classic Electric Launch- Turn Point Design recently completed an electric powered

Launch designed by Tim Nolan Marine Design. Construction was epoxy infused fiberglass

built in one off female molds. All fabrication, lamination, mold work, and fit out

of systems was done at Turn Point Design. The most rewarding feature of the boat,

besides its electric propulsion, was an opening bow with retractable carbon fiber

ramp to make it easier for guests to board the boat from remote beaches. Although

modern materials and construction techniques were used through out the boat, all

parts and systems were detailed to match the 100 year old classic ship she services.